In our sanding block plan you will find few types of the sanding block that you could make in a very short time.

Some of these sanding blocks are designed only for flat sanding and breaking edges while other can be used for round sanding too. Sanding the surfaces is one of the most important operations that needs to be done on wooden parts before the finishing. At the same time, sanding is time-consuming and one of the less interesting parts of woodworking. Besides that, during sanding you should keep in mind that any scar or scratch, regardless of its size, can show up after finishing coats of stain or varnish are applied. The importance of sanding is that this procedure removes hand tool or machine tool marks and smooths the surface of wood. This allows the reflective properties of the finishing materials to equalize and bring out the full beauty of the wood grain. By taking the time and care, using correct procedures and good selected grades of abrasives, the outcome will be finish of perfect quality and appearance. In professional workshops, sanding is done with power sanders (belt sander, pad sander or drum sander) or with sanding machines. In small and less equipped workshops, sanding is still done mainly by hand. Hand sanding also must be done on parts with complicated or complex curved surface as well as on small surfaces. Most woodworkers even after sanding with sanding machines and power sanders do the final sanding by hand.

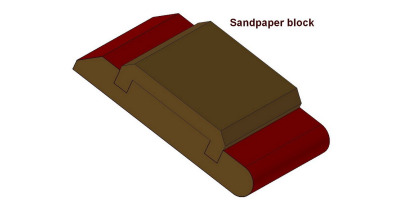

- Sandpaper block: W 76mm (3'') x L 127mm (5'') x H 28.5mm (1.12'')

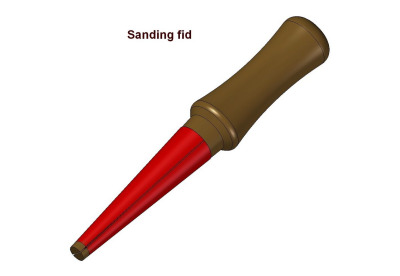

- Sanding fid: D 44mm (1.75'') x L 254mm (10'')

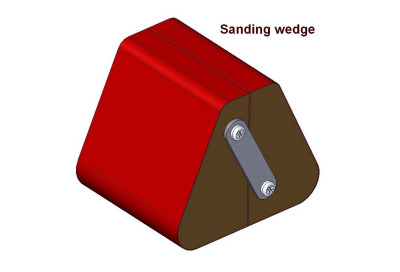

- Sanding wedge: W 90mm (3.54'') x L 76mm (3'') x H 76mm (3'')

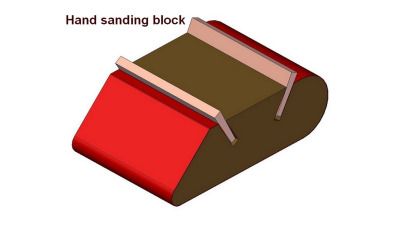

- Hand sanding block: 76 mm (3'') x L 127mm (5'') x H 38mm (1.5'')

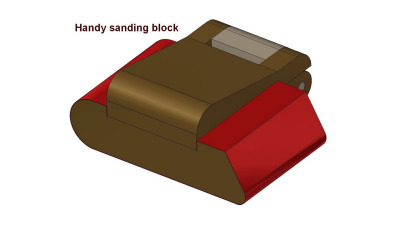

- Handy sanding block: W 108mm (4.25'') x L 127mm (5'') x H 49mm (1.9'')

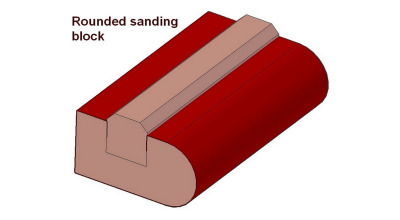

- Rounded sanding block: W 76mm (3'') x L 127mm (5'') x H 44.5mm (1.75'')

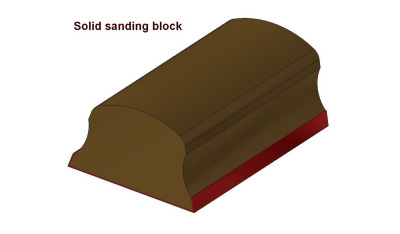

- Solid sanding block: W 63.5mm (2.5'') x L 114mm (4.5'') x H 38mm (1.5'')

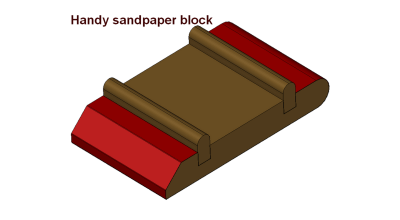

- Handy sandpaper block: W 76mm (3'') x L 127mm (5'') x H 28.5mm (1.12'')

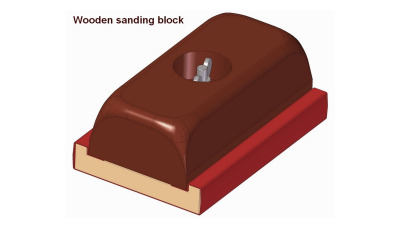

- Wooden base sanding block: W 70mm (2.76'') x L 108mm (4.25'') x H 42mm (1.65'')

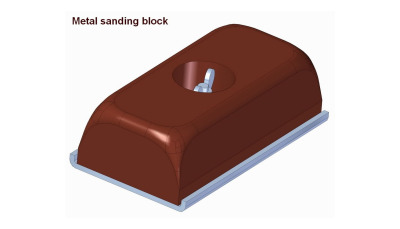

- Metal sanding block: W 63mm (2.48'') x L 108mm (4.25'') x H 34.5mm (1.36'')

For the hand sanding, one of the irreplaceable tools is sanding block. A sanding block makes it easier to hold the sandpaper, maintain flatness of the surface and prolonges life of the sandpaper. Surface on the sanding block that sits on the sandpaper should be slightly resilient. A cardboard, felt pad, cork pad or a rubber pad can be glued on a sanding block in order to become resilient. For large and flat surfaces, use soft padded sanding block. The padding will help to prevent scratching the wood surface by grit caught under the sandpaper. For more delicate and curved surfaces, use very soft padding like a thick piece of foam padding or sponge covered with sandpaper. This kind of padding will shapes itself to the curves, so pressure will be firm and even. For the most sensitive surfaces, the best solution is cushioned padding. It will eliminate pressure providing light abrasion of surface. In the case when crisp edges are essential, use a hard pad. Soft pad will round over the edges, but hard pad keeps the edge square. From the other hand, never use sandpaper to attempt to do the work of an edge tool.

Sandpaper is rated by grit (number of abrasive particles per square inch of the paper’s surface). Good quality of sanding require using progressively finer pieces of sandpaper (for example: 120-grit, 150-grit, 180-grit and 220-grit; or 80-grit, 100-grit, 120-grit, 180- grit and 220-grit). This procedure, called Going through grits, allows each progressive piece of sandpaper to remove the scratches from the previous one. Sanding process usually starts with coarse or medium grit sandpaper and proceeds through finer grits. The moment of shift from smaller to larger grit number is a matter of experience. Basically it is the moment when the entire surface has a uniform look and feel and when you see that further sanding does not improve the sanding surface. For preparatory sanding and levelling off you should start with 80-grit sandpaper. For close grained wood the first coarse sandpaper should be a 120-grit. The final, finest grit depends on the type of wood and type of finish. For final smoothing, hardwood requires higher grit number than softwood. If you will paint the project, you can stop on 120 or 150 grit. For varnish or shellac, 180-grit sandpaper is enough for final sanding. For most delicate work, you should go up to 220 or 240-grit sandpaper. The very fine and extra fine grits are used for between-coats sanding. These recommendations are very general because the grit progression depends on the wood type and project construction. Each woodworker builds their habits based on experience.

Don`t skip grits. It is very important to go through series of grits, because skipping some of the grits will make a lot more work. Always sand parallel to the grain direction. When sanding nearby arise, you should take care to hold the sanding block flat on the surface. During sanding, it is very important to adopt a sanding stroke of uniform length and equalized pressure. Always use sanding block for sanding of flat surfaces because if you will hold the sandpaper only by hand, it will follows the bumps and lumps, and also, it can create the ones.

A piece of cork, rubber or wood with the sandpaper wrapped around it can be used as the simplest sanding block. During the sanding a woodworker holds the block and the sandpaper together by the hand. The problem with this kind of sanding block is that the sandpaper is held only by hand so it still isn't tight enough. It creases, tears and wears out too easy. More complex versions of sanding blocks have various accessories to hold the sandpaper, which make the work with them easier. Besides that, the way of fixing of the sandpaper determines the speed of changing the sandpaper and also unused surface of the used sandpaper.

During sanding, always use protective mask or respirator to avoid inhalation of wood dust. The best solution is use of dust collector or air exhaust, because very fine, almost invisible wood dust particles can cause serious lung damage. During the sanding, it is very important to have good source of light and to look on a workpiece from more than one angle. Depending the type of sanding block, it can be used for sanding of flat, concave and convex surfaces and for every type of edge sanding.

If you customize the width and length of the sanding block pay attention to:

- dimensions of a sandpaper sheet you usually buy – the sandpaper sheet is much larger than you actually need, so you will have to tear it off. Choose the dimensions of a sanding block, so you could make few pieces out of one sandpaper sheet and have no residues, or they should be minimal.

- An ergonomic shape of the sanding block is very important, since it is hand-held during the use.

- For a large surfaces make sanding block as big as possible, because it will save you time and provide better quality of sanding.