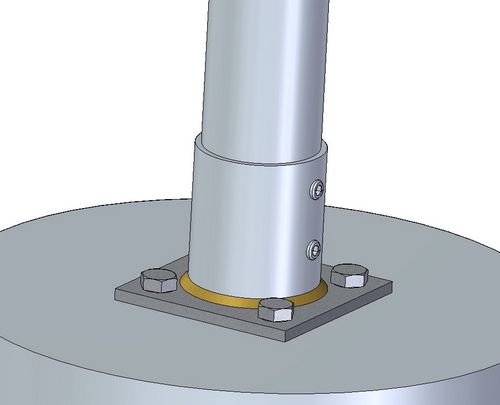

Surface mounted structure rest on top of the ground or safety surface. Surface mount system allows the structure to be attached to the surface (which is usually pre-existing concrete or asphalt slab) with anchors embedded in concrete.

There are many ways to use surface mount systems and all of them differ in what kind of anchors are used. The most frequently used are the following anchors: Concrete Drop-in Anchor, Concrete spike, Sleeve anchor, Anchor bolts (J bolts)... All the mentioned kinds of anchors can be purchased at almost any hardware store. In the following pictures you can see several ways to use the surface mount system.

Surface mount system - DIY variants

- Surface mount with concrete drop-in anchor

- Surface mount with sleeve anchor

- Surface mount with J-bolts

- Surface mount with concrete spike

Surface mount system in industrial conditions

- Surface mount with anchor plate cover

The choice of the kind of anchor depends on several factors:

- the loads acting on the construction;

- the base material onto which the structure will be installed;

- whether the structure will be permanently installed or there is a possibility for its removal and

- the foundation thickness.

- effects of corrosion

Surface mount systems provide a solid and stable connectedness of the structure and the surface, but also easy disassembly which is very convenient if the structure needs to be replaced or moved. Solid concrete is the best base material for surface mount.

There are variations of the surface mount system.

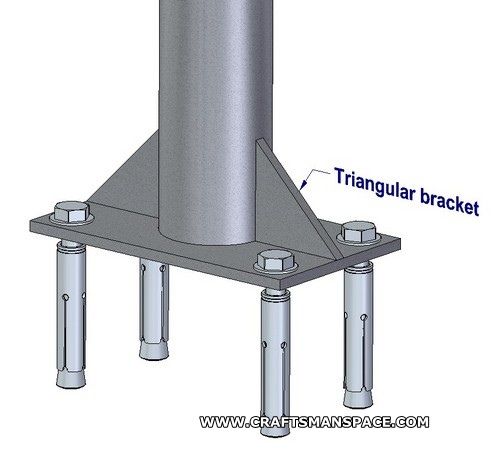

Gusset mount system

Gusset mount system is used for additional stability and solidity of the structure. Gusset mounts are similar to surface mounts, the only difference is the addition of triangular reinforcements between the structure’s legs and the plates welded to their ends. On the next picture you can see the gusset mount system. This method of mounting is used for structures that are high or long.

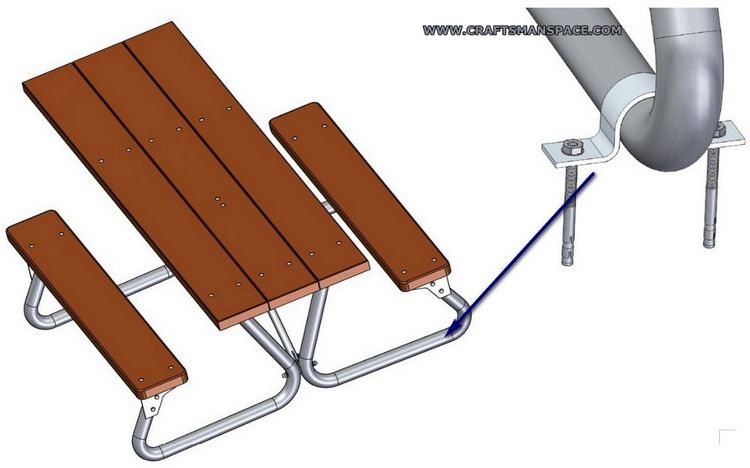

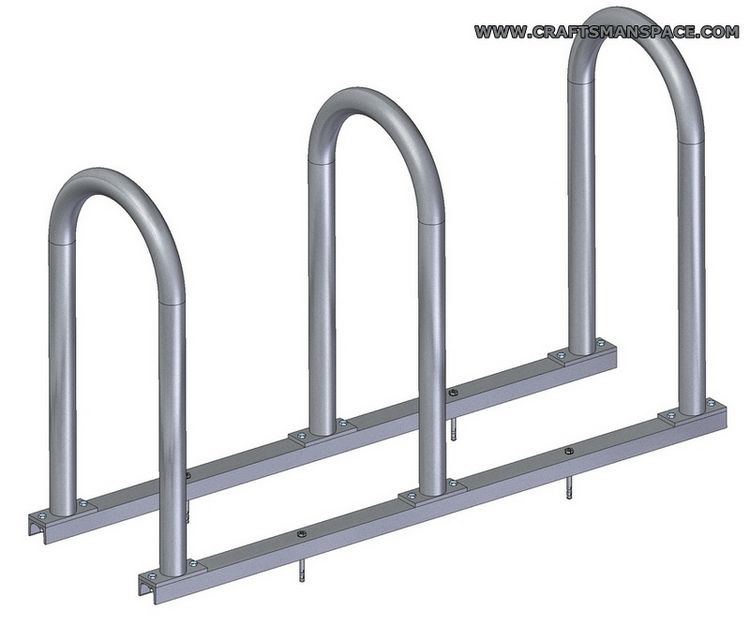

Rail mount system

With the rail mount system several structures can be attached to the surface. Rail mounts are a variation of surface mounts and they are used in such a way that a few structures are welded to a rail which is fixed to the surface with the help of surface mount system.

On the next picture you can see the rail mount system.

U-Bracket surface mount system

Structures that have legs which are not normal in relation to the earth’s surface are mounted with the help of U-bracket surface mount system.

On the next picture you can see the U-bracket surface mount system.