In this section of our website you can find free projects for the hand tools that you can make by yourself.

We tried to offer you the plans for hand tools that are simple enough so you could make it by yourself without big investments, and at the same time, these tools will be a great help when working in the workshop.

Anyone who has tried to make or repair something, quickly realized that it is practically impossible to do that work without the appropriate, quality hand tools. Hand tools are here to make our work easier and allow us to do our work quicker and better. Without the proper tool or machine, and without the knowledge on how they operate, do not even try to do any kind of work, because you will either get injured or spend much more time in doing some work, and what the worst thing is that you will probably do it wrong.

You do not have to spend a fortune to achieve good results in your work – instead of buying some hand tools, think about making it yourself and enjoy the result. The quality of your work depends mainly on your experience and skills, but also on the quality of materials, tools and machines that you use. It is not enough just to have a good tool or machine for the excellent work result without the skilled hands that will use them.

Hand tools will always be present and necessary in the workshops, because the investment in specific machinery that could replace hand tool for the manufacture of individual objects or small series of products is often not worthwhile. In the small workshops, those specific machines will not be fully employed, which is necessary if you want these machines to be profitable. Another reason for the hand tools endurance lies in the fact that each beginner has to master the tools and techniques of work in order to become a skilled craftsman. If the machines work instead of him, that is no longer a craft, but the industry. One more reason for the survival of hand tools is the fact that top craftsmen leave their personal mark on their work and each object they manufacture is unique. This can not be achieved with the machines.

If you need 3D models of hand tools, please visit the special category named 3D models of hand tools.

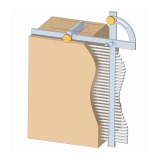

With this simple tool you will be able to carry sheets of plywood or some other material all by yourself.

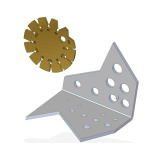

On this page we are offering you two plans to help you create bevel gauges for checking sharpening and most common angles.

Here we are presenting a free woodworking plan that will allow you to make Bevel square hand tool.

The center square (center line finder) enables you to accurately locate the center of a round stock. Center line finder enables you to accurately locate center (middle) line of a board (edge, face or end).

With the free metalworking plan that you can download on this page you can make a Contour gauge.

Here we are presenting a woodworking project that will allow you to quickly create a simple and practical cutting gauge hand tool.

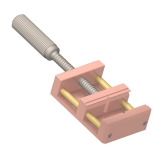

This is a free plan for you to make a vise for your bench mount or floor mount drill press.

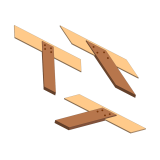

Here you can download free "do it yourself" project for making an engineer's sliding T bevel.

With the free project that you can download on this page you can make an engraving vice, one of the most commonly used tool of every engraver.

With the free project that you can download on this page you can make a fence post driver, a useful tool if you live in the countryside.

Mitre gauge is a wooden measuring tool with two pieces of wood (one i s a blade, the other stock) that are at fixed angle to one another, and this plan represents mitre gauge for 30, 45 (mitre) and 60 degree angles.

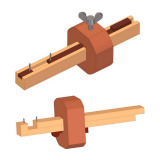

On this page you can find two free woodworking plans that you can use for making Mortise gauges.

On this page you are offered two simple laser cutting projects for making portable extension cord organizers.

In our sanding block plan you will find few types of the sanding block that you could make in a very short time.

In order to help all those who need to make a new handle or replace a poor quality handle on their saw, on this page we offer you 32 templates for various types of saw handles.

We decided to present you a shaving horse plan which proved very well in the practice, and which differs from most shaving horse plans we have seen so far.

On this page we present the free project for a simple sheet metal bench shear manufacture, which should be an integral part of every metalworking shop.

Here you can find a plan according to which you can make a sliding bevel square which can also be found under the name sliding T-bevel.

With this plan you can make a very simple standing press. The plan was made on the basis of a press seen in a workshop.

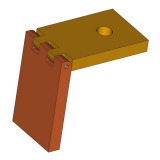

Here you can download a free woodworking plan which will help you to make a simple tool which we called straightedge tool for corners tool.

Here is a free woodworking project according to which you can make an ergonomic and sturdy sawhorse with a mounted vise.

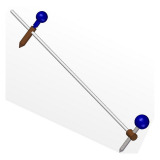

The free metalworking plan presented here contains drawings with which you can make a trammel, i.e., a beam compass.

Here we are presenting a woodworking plan that will allow you to make a simple and useful Try square hand tool.

This category of our site contains a variety of free DIY plans on how to make different kinds of hand tools. In this category you can find plans with the tools dimensions and directions for their construction, and if you are interested in the proper use of tools, you can visit our category HAND TOOLS AND USE, or download and read some of the books from our category FREE TECHNICAL BOOKS.

Hand tools are one of the most important factors in the work of each craftsman, and the choice of tools and machines which you will own and use should be given a great consideration. It is not important only to have as much different types of tools as you can get in your workshop - their quality is also a thing that matters. There is an old proverb that has a lot of truth in it: “A bad craftsman always complains of his tools. A good craftsman can use anything.”. Of course, almost none of the good craftsman will allow himself to use bad hand tools or not maintaining his tools regularly, because they are his basic instruments of work, so the purchase or manufacture of high-quality hand tools and care for them are the basic necessities of a good craftsman.

We can say that the quality of some craftsman work can be pre-estimated by the condition of his tools. The workshop does not have to be equipped with expensive tools or tools that are nice to look upon - a good craftsman is recognized for maintaining his hand tools in perfect condition. Every good craftsman knows that the most important fact is not to own the most expensive hand tools, but the fact if that tools are functioning properly, if the cutting edges are sharp, the material out of which hand tool is made is appropriate and quality, and the handle of the tool has an ergonomic shape. Each beginner should know that being a good craftsman does not mean just to own a set of expensive hand tools, but to go through a good practice in using tools, proper use of tools and then training of the acquired knowledge. - ”Practice makes perfect!”

Beginners should only purchase machines and hand tools that are enough for their initial steps. With the improvement of their skills in the workshop, they should buy hand tools that they feel the need for. Each craftsman has its own individual working methods, and in accordance with it, they supply their workshop. It is often the case, that one tool really helps and saves the time for one craftsman, while it is completely useless for the other one. Therefore, do not listen to dealers advises on what to buy. Their job is to sell as much as possible. You need to know exactly what do you need and why do you need it. A properly equipped workshop does not have any hand tools that are not in use.

While working, you will often require some specific hand tools that you can not buy, so you will either have to make it, or you will have to improvise. A special hand tool manufacture requires knowledge and time, and you should think twice about whether it is worth to make it.

If you are involved in woodworking or some other craft, it is not important to buy all the tools, power tools or machines at once, or to have a large space where your workshop will be – rather think carefully about which hand tools and machines you need the most, and you will purchase other hand tools in time, from the earnings that you will get by selling your products. If you are buying equipment for your workshop in order to earn money from this work, make decision about each investment based on expectation if it will bring you more money than it was invested in.

As it is previously mentioned, you should have the high-quality hand tools, but this does not mean that you will have to buy the most expensive hand tools on the market. The most expensive hand tools in the fancy-shops are not always the best choice. On the other hand, do not buy cheap tool kits designed for amateurs either, because they are not the quality tools. With these tools you will do a few jobs and they will break up or deform, because the steel for their manufacture often does not undergo the appropriate heat treatment. Ask around about who are the dealers that sell quality hand tools at a reasonable price. If you can, consult with the colleagues on where they have bought their hand tools and are they satisfied with it, or buy only from respectable tool dealers, who focus not only on earnings, but also on the reputation on the market. The price of a high-quality tool does not vary much depending on the manufacturer.

Hand tools should be well maintained and should not be allowed to rust - this way they will quickly become unusable. Pay special attention if the hand tools are not used daily. Oil the hand tools that you are not using often after each use, and always put them back on their place. A special attention should be paid to the cutting tools. Their cutting edges must be sharp, because you cannot do quality work with a dull cutting tool. Sharpening some tool can be tedious, but if you sharpen it regularly - as soon as you notice that it is dull - the procedure will come quite easier, than when you wait and need to sharpen a lot of them at once.

Rules:

- the tool is useless if you can not find it. Keep your workspace organized and hold each tool in its place in the workshop,

- keep the tools in good condition. Protect your tools from rust and keep them sharpened,

- use each tool only for the intended work,

- always keep tools at hand, but take care so they cannot fall on the floor or machine,

- do not use damaged tools,

- whether you use hand tools, power tools or machines, at first learn about how the tool is used properly and study all aspects of the safe use.