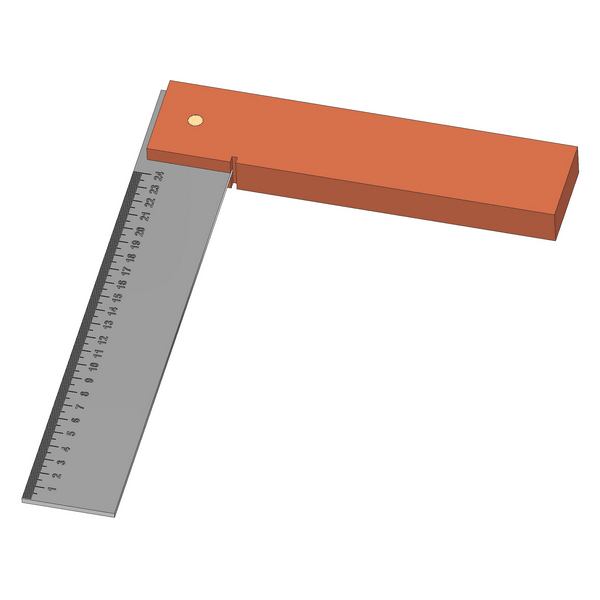

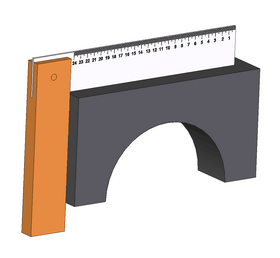

The try square has a blade (straight edge) and a stock (beam) which are fixed together at exactly 90. The stock is much thicker than the blade. The edge of the blade and the stock are perfectly sharp and straight.

The try square may be made entirely of steel or wood or it may have a stock of wood and a blade of steel. The blade have metric or imperial graduations or a combination of both.

If you need 3D model of a try square, please visit this page: Try square 3D model

The try square is used mostly for:

- Laying out lines perpendicular to an edge or side of a board

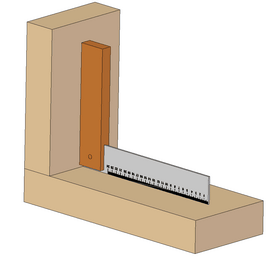

- Checking edges and ends of boards to see if they are square with adjoining surfaces

- Checking the width or thickness of narrow boards

- Measuring short distances

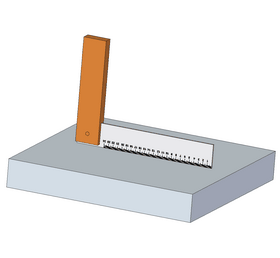

- Checking flatness

|

|

| Marking on an edge | Marking on a side |

|

|

| Checking outside corner | Checking inside corner |

|

|

| Checking flatness | Measuring short distances |

In order to keep the try square accurate, care should be taken not to drop it. All the angles of the square, exterior as well as interior, must be perfect right angles.

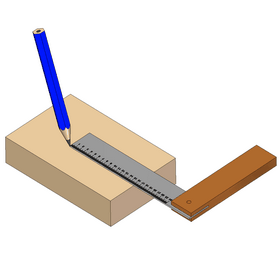

If a try square is suspected of not being accurate, it may be tested easily. Use a board that has a perfectly straight edge

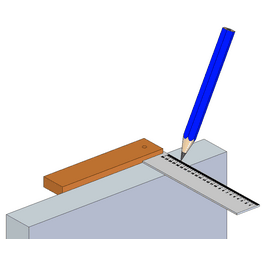

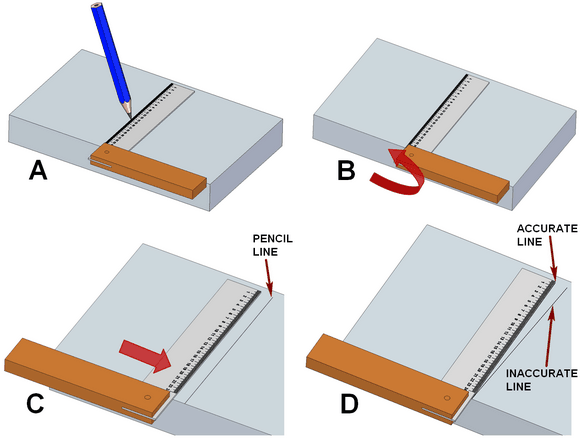

- Place the stock of the try square against a perfectly straight edge of a board which is wide enough to allow a pencil line to be made the entire length of the blade. Draw a line across the face along the blade of the try square. (picture A)

- Turn the try square over (picture B)

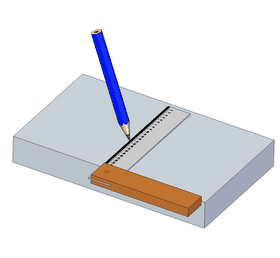

- Holding the stock against the same straight edge, move the blade to the previously marked line (picture C)

- If the try square is accurate, the pencil line and the edge of the blade will perfectly coincide. (picture D)

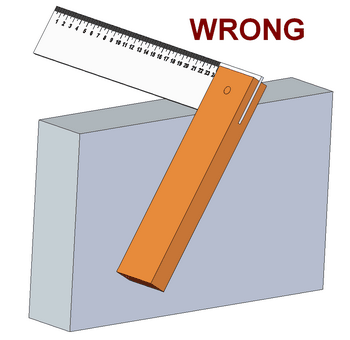

Always keep the try square at right angles to the surface.

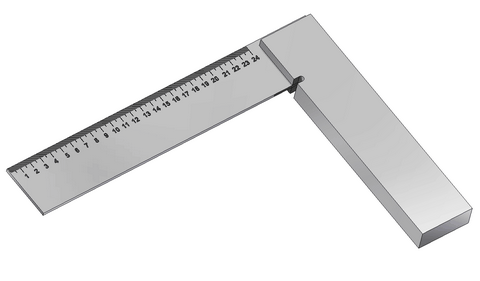

ENGINEER’S (MACHINIST) SQUARE

A engineer's square (machinist square) is the metalworkers' equivalent of a try square. Machinist try squares are made entirely from metal to guarantee accuracy. A notch is cut in the stock in line with the inside edge of the blade for accurate measurement even when there is a burr on the edge of the work.